Do you have questions about our sensors?

Contact our torque sensor and force sensor experts for advice.

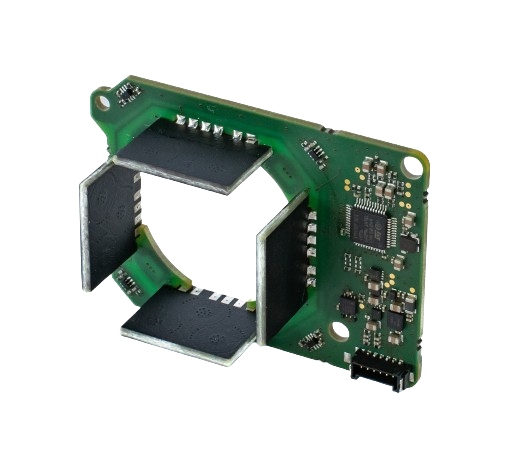

Torque sensors for non-contact and reliable measurement of surface tensions on a shaft. The sensor's operating principle is based on an active measurement principle that requires a ferromagnetic material. By generating a magnetic field, the measurement is particularly insensitive to external influences.

Force sensors for non-contact and reliable measurement of tensile and compressive stresses in various components. The sensor's operating principle is based on an active measurement principle that requires a ferromagnetic material. By generating a magnetic field, the measurement is particularly insensitive to external influences.

Our measuring principle is based on an active method. Local generator coils generate a magnetic alternating field that penetrates the surface of the measurement body. The voltages at the material surface cause changes in the magnetic field, which in turn lead to signal variations in the secondary coils. These signal changes are converted into a torque or force signal and outputted typically via CAN or SPI.

Magnetic interference or overload have no influence on the sensor functionality, maintaining consistently high performance.

Through simple and cost-effective implementation, we have a cost advantage over competing products.

Due to contactless measuring, the lifespan is significantly increased.

Oil, water, rust, dust, or other contaminations cannot affect the sensor.

Magnetic interference or overload have no influence on the sensor functionality, maintaining consistently high performance.

Through simple and cost-effective implementation, we have a cost advantage over competing products.

Due to contactless measuring, the lifespan is significantly increased.

Oil, water, rust, dust, or other contaminations cannot affect the sensor.

Contact our torque sensor and force sensor experts for advice.