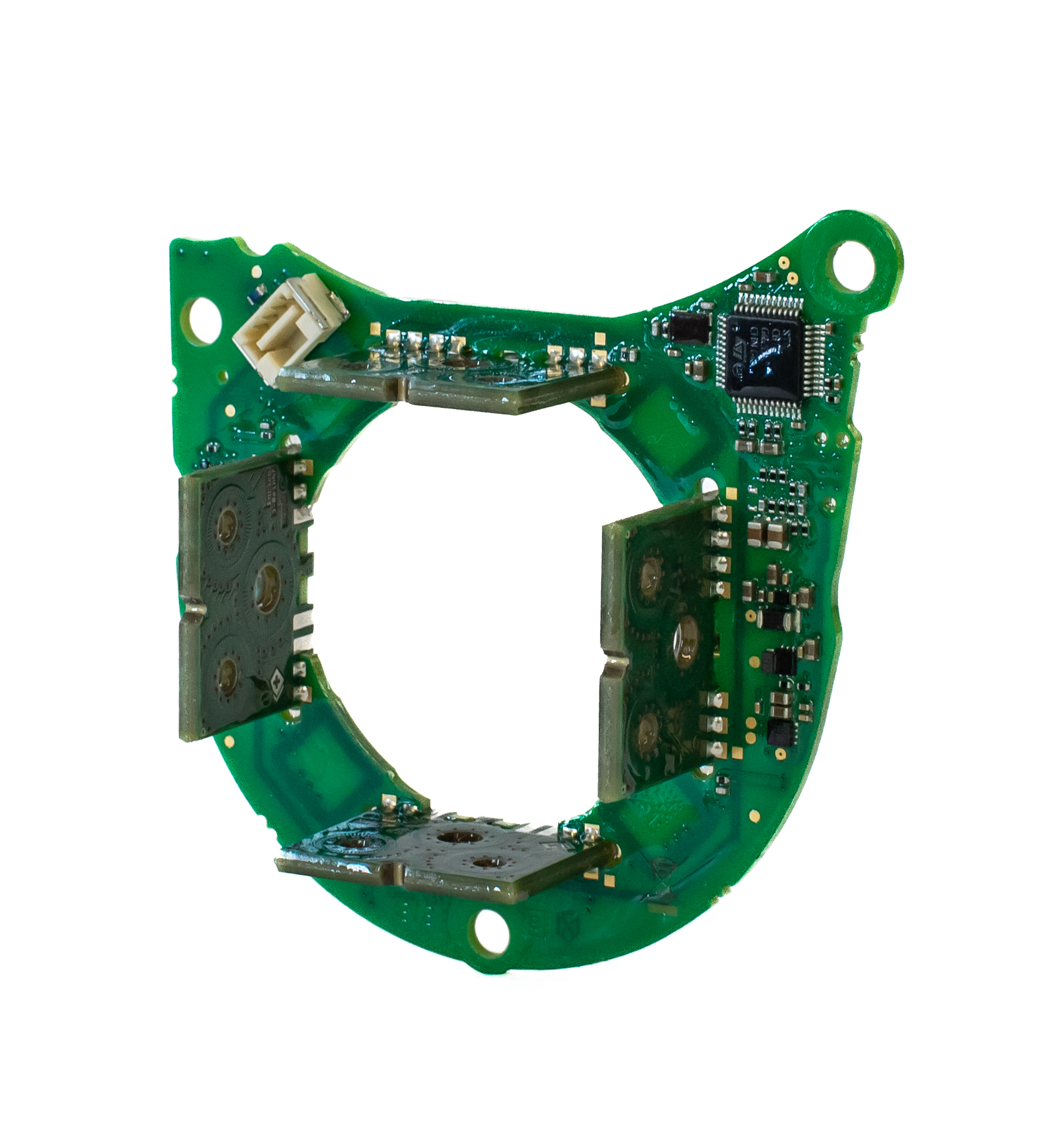

Mechanical sensor module (must be mounted on the measurement shaft)

Do you have questions about our sensors?

Contact our torque sensor and force sensor experts for advice.

The contactless and active sensor solution based on the magnetostrictive principle consists of the following individual components:

Mechanical sensor module (must be mounted on the measurement shaft)

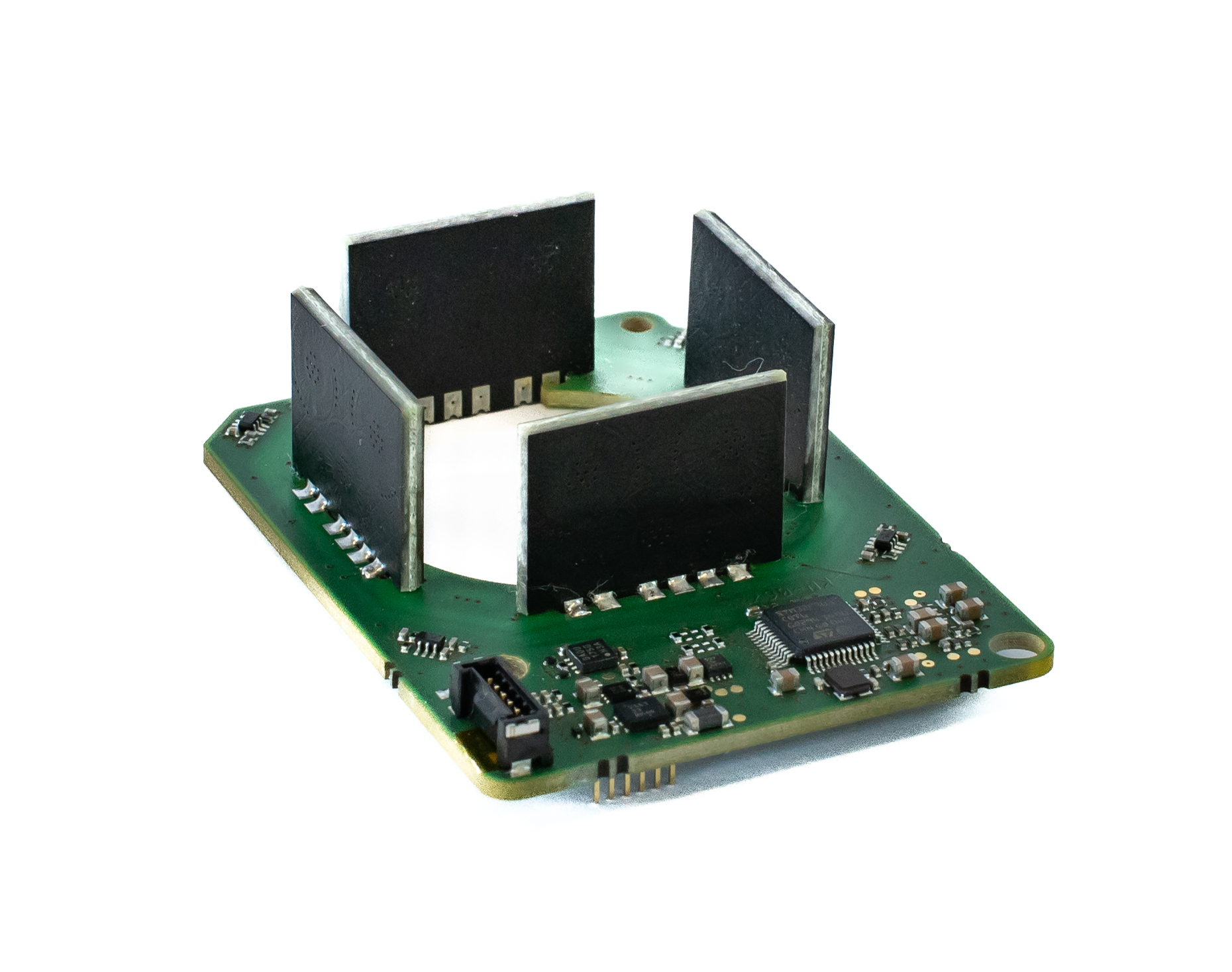

Sensor electronics (integrated into the sensor)

Our multi-force sensor works with most ferromagnetic test objects (for example: solid shaft, hollow tube) and can be used to measure torques, bending forces, and axial forces.

The sensor module from Magnetic Sense is placed on the ferromagnetic test object where the measurements (e.g. torque) are to be taken. The sensor element inside the module emits a magnetic alternating field, which penetrates the surface of the test object. The mechanical forces acting on the test object influence the magnetic alternating field and its properties. These changes are detected by the sensor element and passed on for processing in the sensor electronics.

Measurement values through magnetic interaction with the measurement shaft

Very high system dynamics with a measurement output of 1kS/s

Rust, dust, and oil do not affect the measurement results

The sensor can be integrated into various customer-specific applications through adjustments

Adaptable to various applications through a modular kit

Through integrated temperature compensation, a measurement range of -20 to 125°C can be achieved.

No damage from mechanical overload

Reliable and robust measurement signal

Measurement values through magnetic interaction with the measurement shaft

Very high system dynamics with a measurement output of 1kS/s

Rust, dust, and oil do not affect the measurement results

The sensor can be integrated into various customer-specific applications through adjustments

Adaptable to various applications through a modular kit

Through integrated temperature compensation, a measurement range of -20 to 125°C can be achieved.

No damage from mechanical overload

Reliable and robust measurement signal

We offer our customers the opportunity to develop a sensor that meets their needs and requirements.

In addition to custom solutions, standardized products are also available from us.

Contact our torque sensor and force sensor experts for advice.