Any ferromagnetic, hardened measuring point is suitable

Do you have questions about our sensors?

Contact our torque sensor and force sensor experts for advice.

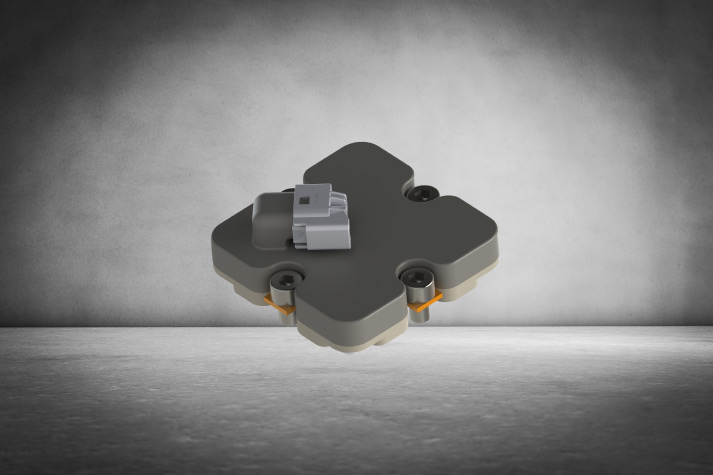

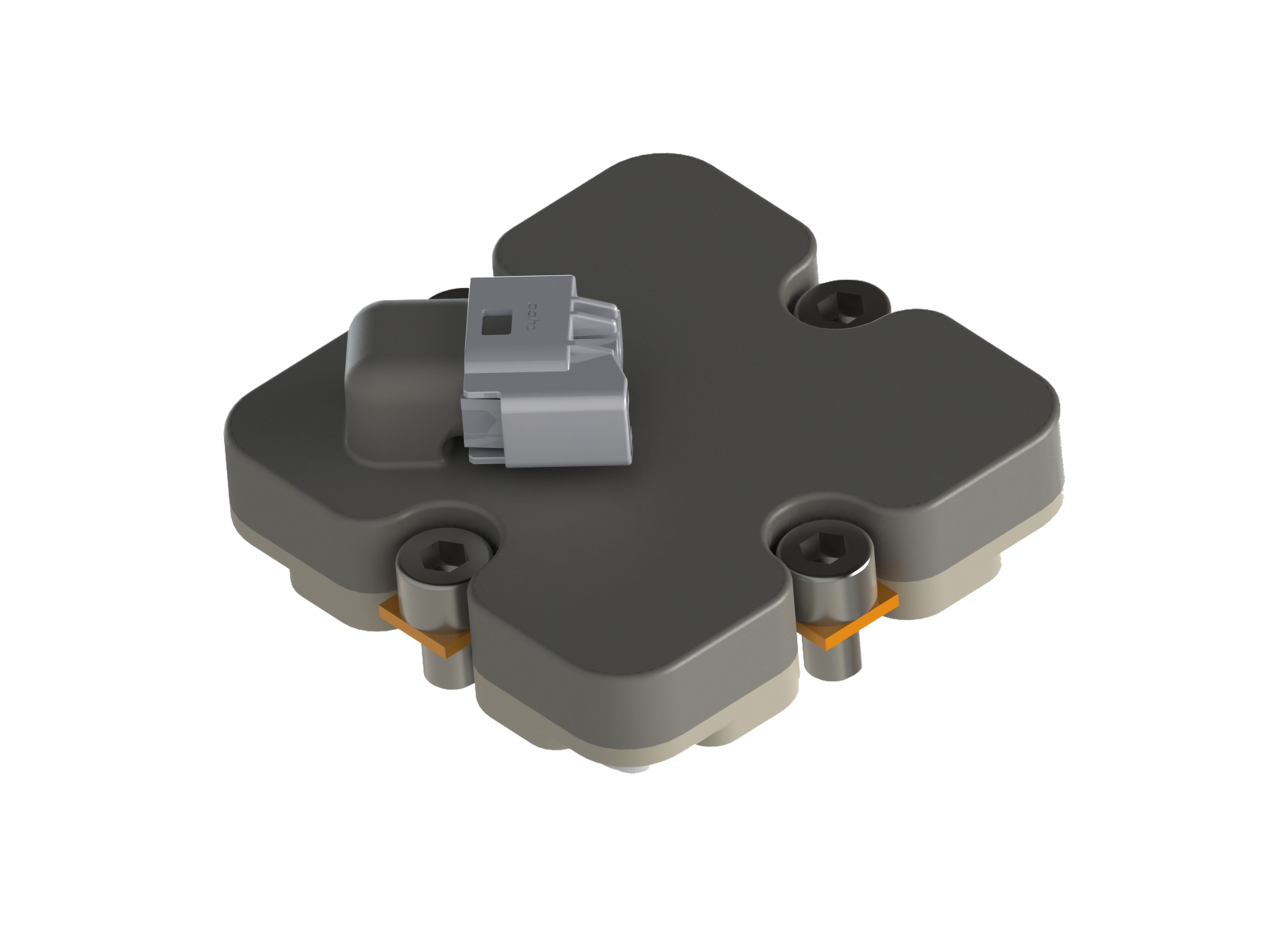

The sensor module is mounted on the ferromagnetic test object where the measurements (e.g., axial force) are to be taken. Inside, the sensor module emits a magnetic alternating field that penetrates the surface of the test object. The mechanical forces acting on the test object influence the magnetic alternating field and its properties.

These changes are detected by the sensor element and passed on for processing in the sensor electronics. Subsequently, it is outputted how much force is acting on the object.

Our multi-force sensor works with most ferromagnetic test objects (for example: solid shaft, hollow tube) and can be used to measure torques, bending forces, and axial forces.

The sensor module from Magnetic Sense is placed on the ferromagnetic test object where the measurements (e.g. torque) are to be taken. The sensor element inside the module emits a magnetic alternating field, which penetrates the surface of the test object. The mechanical forces acting on the test object influence the magnetic alternating field and its properties. These changes are detected by the sensor element and passed on for processing in the sensor electronics.

Contactless measurement through magnetic interaction

High signal bandwidths possible

Insensitive to overload as the sensor is not in the force flow

Integration of the force sensor even in the smallest space

Modular kit for various applications

Large temperature range due to suitable components

High long-term stability

Insensitive to interference

Contactless measurement through magnetic interaction

High signal bandwidths possible

Insensitive to overload as the sensor is not in the force flow

Integration of the force sensor even in the smallest space

Modular kit for various applications

Large temperature range due to suitable components

High long-term stability

Insensitive to interference

The force sensor can be used at many measuring points made of ferromagnetic material. The measuring shaft should also be hardened and demagnetized.

Material parameters can be set by initializing the sensor. In order to achieve high accuracy, it is necessary to perform a two-point calibration.

The two-point calibration involves applying a load to which the measured sensor value is normalized.

Any ferromagnetic, hardened measuring point is suitable

Contactless measuring principle

Digital interfaces

No influence from magnetic interference fields

Insensitive to water, oil and dust

No limitations in speed

No magnetization of the shaft required

No damage to the sensor due to overload

Various shaft diameters can be realized

We offer our customers the opportunity to develop a sensor that meets their needs and requirements.

In addition to custom solutions, standardized products are also available from us.

Contact our torque sensor and force sensor experts for advice.